Your shopping cart is empty.

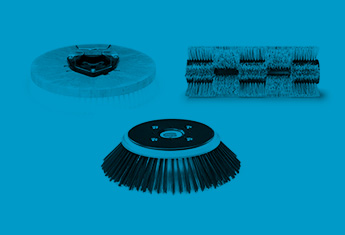

Disc vs. Cylindrical Brushes 101

Posted in Cleaning Solutions, Best Practices, Cleaning Challenges,

An in-depth overview of floor scrubber brush types, applications and proper brush maintenance

Floors scrubbers are available with both disc and cylindrical heads for use in a variety of applications. The disc scrubber is commonly found on smaller, walk-behind scrubbers and larger battery-powered rider scrubbers. These cleaners may use a disc pad to polish a floor or a hard-bristled brush for a more deep clean.

For cleaning, water is dispensed down into the centre of the brush(es). These brushes sit flat against the floor at speeds of 250-300 RPM. The brushes are primarily intended to wash a floor or strip wax from a floor. Disc brushes can be made of a variety of materials, including nylon, polypropylene and abrasive bristle. The specific type depends on what type of floor is being cleaned. Regardless, these machines have no mechanism for picking up debris so floors must be manually swept before using this type of brush.

Cylindrical scrubbers are comprised of a pair of cylindrical brushes that turn in opposite directions at speeds between 600 and 800 RPM. Water is spread via a drip tray that sits in front of the brushes. The motion of the brushes throws loose dirt and particles into a tray that's emptied by the operator after cleaning is completed. This eliminates the need for pre-sweeping before scrubbing. Cylindrical brushes can be made from the same types of materials as disc brushes.

Floor Applications for Disc and Cylindrical Brushes

Disc brushes are ideal for use on finished floors in a setting where floors tend to get scuffed and need to be polished regularly. This might include schools, retail stores and healthcare facilities. When a more aggressive type of disc scrubber is used on a walk-behind machine, floors in industrial settings can be cleaned. Because of the down pressure used to operate a disc machine, very heavily soiled floors can be addressed. Disc brushes are the preferred technology for:

- Flat Surfaces

- Vinyl Composition Tile (VCT)

- Sheet Vinyl

- Polished Concrete

Cylindrical brushes are great for large, open areas that aren't conducive to pre-sweeping or those that have grout or cracks where dirt can become trapped. Food and beverage manufacturers, parking facilities, warehouses and other types of production facilities are ideal candidates for this type of brush technology. Floors that would benefit from cylindrical cleaning include:

- Natural Stone

- Rubber Studded

- Safety Floors

- Carpet

- Laminate

Benefits of Each Type of Brush

While each is effective at cleaning a floor, there are clear advantages to each type of brush. Here are a few things to consider when deciding which is right for your facility.

Disc Brushes

- Able to accommodate pad drivers which are used for maintaining waxed floors.

- Can remove thick build up since these are able to create more down pressure.

- Versatility of tools (pads and brushes) for cleaning and polishing.

Cylindrical Brushes

- These machines can sweep and scrub simultaneously.

- No dust is created since sweeping is done wet.

- Ability to clean grout lines.

- Working at a higher RPM provides for more effective cleaning overall with this technology.

Properly Maintaining Disc and Cylindrical Brushes

Either type of brush will need to be replaced periodically. Like anything that comes into contact with a hard surfaces on a regular basis, the brush bristles will wear down over time. There's no magic formula to determine how long a brush will last. It depends on how often it's used, the type of floor it's used on, and the condition of the floor, how dirty it is and how fast the operator cleans the floor.

For disc brushes there is often a wear indicator built into the brush itself that when it is reached the brush should be changed. On cylindrical machines brushes should be replaced when the brush bristle is about ½” or 1 cm. You may also notice that it's taking longer or more passes are needed to clean the same floor. This is a sign the brush needs to be replaced.

You can prolong the life of brushes by cleaning them after each use. Removing dirt, stripper, finish, wax and anything that may be wrapped around the brush will help the brush stay in good working condition. Simply spray the brush off using hot water and hang it to dry. You can also consider rotating cylindrical brushes on a weekly basis. By rotating the brushes (front to back and back to front), you can prolong the lifespan.

Both cylindrical and disc machines can be an effective way to clean a wide variety of floors and offer their distinct advantages, but ultimately the choice comes down to the type of floor you need to clean.

RELATED LINKS