Your shopping cart is empty.

A Preventative Maintenance Checklist for Your Equipment

Preventative Maintenance Checklist for Your Equipment

Posted in Best Practices, Cleaning Challenges,

Aging Machinery Maintenance Tips

Your cleaning equipment is durable. Your equipment is well-maintained.

But…your equipment is used every day.

Aging equipment can be a drain on staff time or even a potential hazard if there’s a break-down during use. Maintaining aging equipment requires preventative machine maintenance with special attention to areas that are common sources of service issues. The preventative maintenance checklist found below discusses equipment maintenance tips that can help increase the useful life of your aging machines.

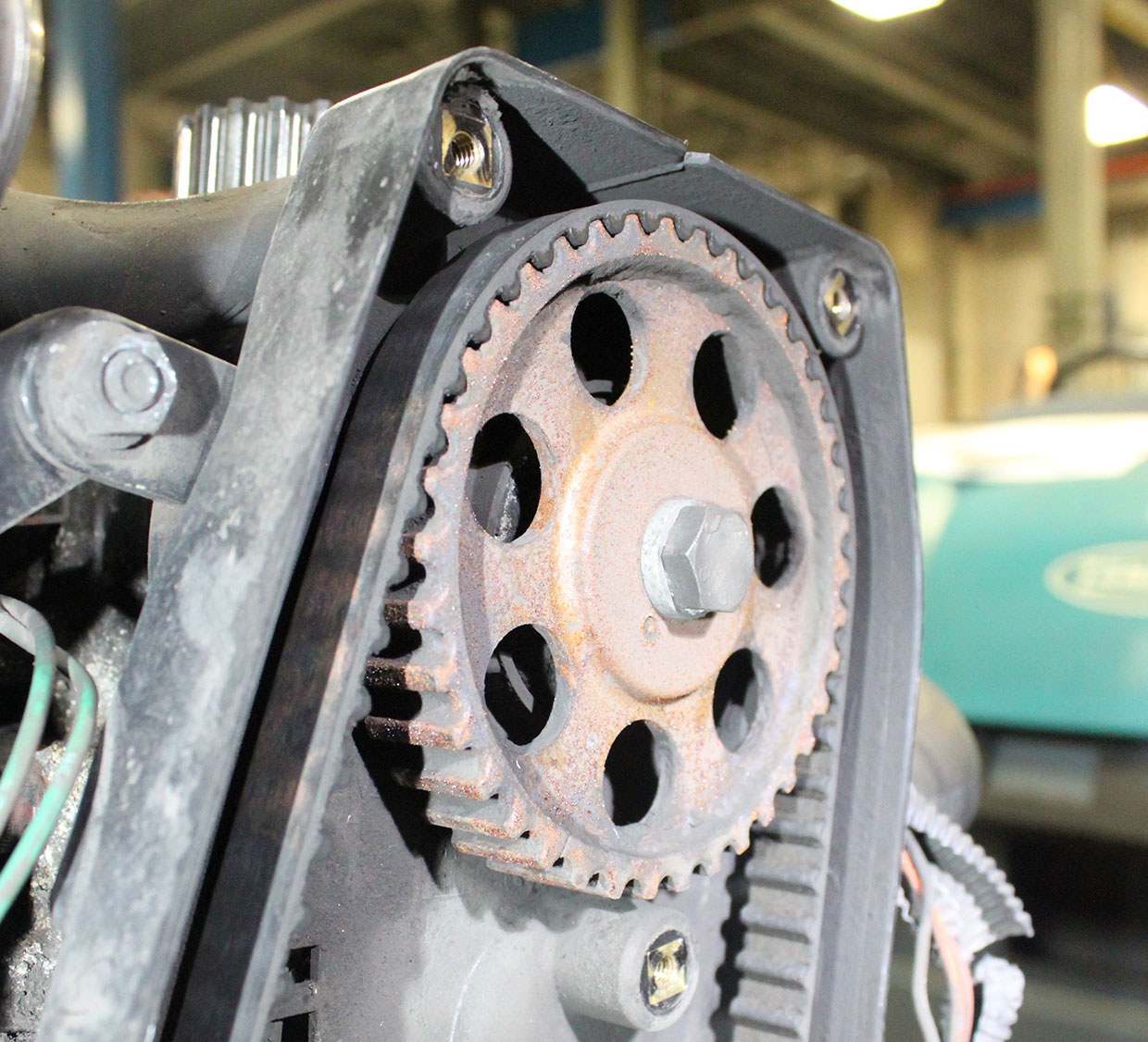

Timing Belts

If the belt has been in use for 200+ hours or is used in a harsh environment, check for wear & tear, cracks, shredding, or slack.

Fuel Systems

Check the fuel hose and feed lines for signs of age or wear. Listen to the engine and note if it revs and then chokes off.

Brush Housing / Motors

Check for debris, cracks, or corrosion in the housing. Be aware of changes in spin rate, vibration, or noise during operation.

Squeegee Linkage

Note water trails on the ground, and check to make sure the linkage system is parallel to the ground and centered on the machine. Watch for corrosion near water collection points.

Engine Valves

During service, check for wear on older or heavily used equipment. Note if equipment is using fuel at an increasing rate.

Rusted Parts

Watch for surface rust deepening or pitting metal components.