Your shopping cart is empty.

An Ounce of Prevention

Posted in Productivity, Cleaning Challenges,

Preventative Maintenance for Equipment

The old saying goes: “An ounce of prevention is worth a pound of cure.” True in many situations, these words certainly apply to performing preventative maintenance on mechanical equipment. Whether it’s scheduling regular oil changes for a car or following a recommended plan for facility equipment maintenance, routine preventative maintenance usually saves headaches – and money – in the long run.

It may seem unnecessary to disrupt schedules to service a piece of equipment that’s working, but preventative service calls offer many benefits:

- They can prolong the life of your equipment

- They may reduce unplanned, costly downtime caused by equipment failure

- They maintain the reliability of equipment by keeping parts in good working order

- They reduce the potential for expensive repairs when equipment fails and must be fixed quickly

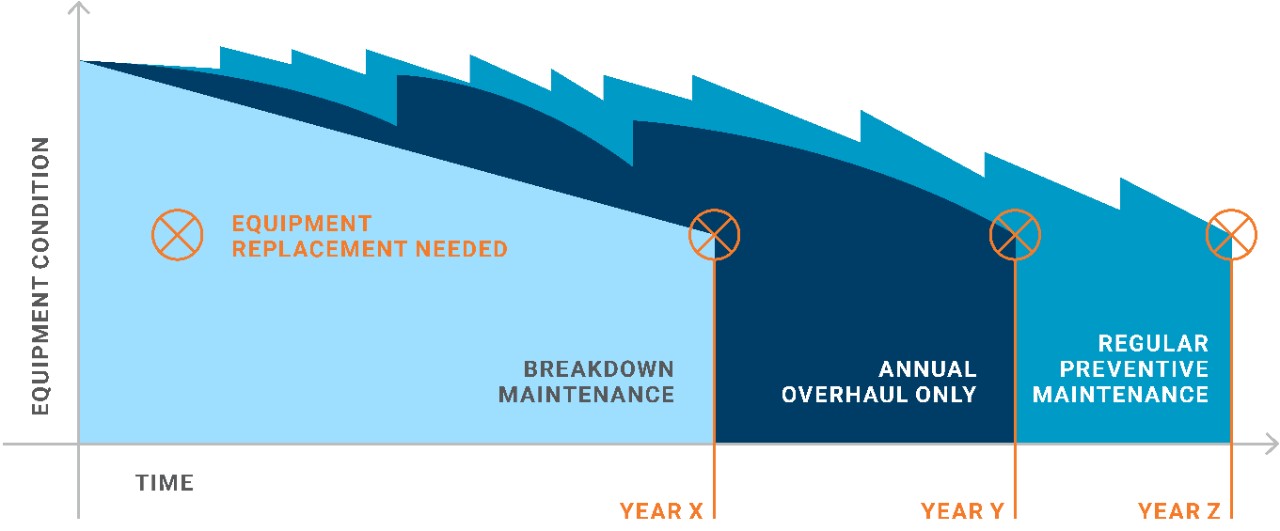

In fact, preventative maintenance can be an important part of your equipment investment. The graphic with this article shows a generalized view of how different approaches to service affect the overall life of a piece of equipment. The wear and tear on equipment that’s serviced only when it breaks down shortens the machine’s life. Performing annual maintenance helps, but as the graphic depicts, a regular schedule of preventative maintenance prolongs the equipment’s useful life, extending the use that a facility gets from their purchase.